Description of Recycled Paper Making Machine:

This machine includes beater, refiner, potcher, agitator, pulp pump, desander, machine for rewinding and perforating and embossing.

It is operated by 3 people, and produces about 1-2 ton per day.

This series equipment can be used in many ways, it can product toilet paper, napkin paper, facial tissue paper and so on. It can take full advantage of local resources, such as waste paper.

Workflow for paper making machine

Waste paper, hydrapulper, vibrating screen, centrifugal screen, propeller, bleacher, refiner, pulp tank, pulp pump, pressure sieve, pulp tank, pulp pump, sand remover, scoop pump, cylinder mold, paper machine, jumbo roll, rewinder, bobbin paper cutter, napkin folder, finished paper.

1. Toilet paper machine (rewinder machine - cutting paper machine - small roll paper)

2. Napkin paper machine (plate paper slitting machine - napkin paper machine - napkin paper)

3. Facial tissue paper (plate paper slitting machine - facial tissue paper machine - facial tissue paper)

Functions and Features:

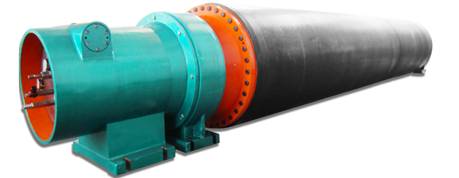

1. cylinder section: diameter 1000mmx1100mm stainless steel cylinder mould 1set, diameter 260mmx1100mm couch roll 1set,coated by rubber, rubber shore hardness 38°Cą2.

2. dryer section: diameter 1250mmx1100mm cast iron alloy dryer can 1 set, diameter 300mmx1100mm touch roll 1set,1group scraper knife. rubber shore hardness 90°Cą2. Mechanical pressure device.

3. paper cutting section: 787mm slitting machine 1 set .

4. drive and control section: Alternating current , speed control , section drive

Technical parameters:

|

Model |

787 |

|

Net paper width |

787-900mm |

|

Working speed |

20-80m/min |

|

Paper weight |

15-140g/m2 |

|

Capacity |

1-1.5ton/day |

|

Width of cylinder |

Diameter 700x1100mm(stainless steel wound cylinder) |

|

Dryer can |

Diameter 1000x1100mm(cast iron alloy dryer) |

|

Rail gauge |

1300mm |

|

Drive way |

Decelerator drive(type250) |

|

Dimension |

5100x1600x2000mm |