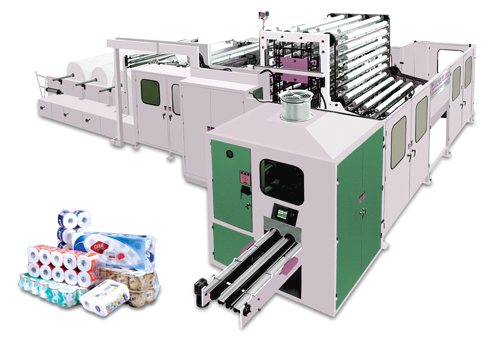

Descriptions of High speed automatic toilet paper machine:

This equipment is to perforate and cut the raw paper into various sizes according to the requested. The finished product is neat, in good order and with equality tension. It has the feature of compact structure, easy and stable operation, less electricity consumption. This equipment is adjustable to meet the requested finished product. This model is the ideal equipment for paper making factory and paper processing factory.

This machine is consist of stand of raw material, paper conveying unit, embossing unit, perforating unit, rolling unit, electricity control and cutting system.

Working process:

Unreeling — Embossing — Perforating— Lamination— Rewinding— Tail-gluing— Edge trimming— Automatic core loading .

Functions and features:

1. This model is designed with computer control system, fully automatic in production process, the function is complete and the production speed is high.

2. It can automatically change the core, spray the glue and seals without stopping the machine and also automatically raise and lower speed when exchanging the core.

3. When change the core, the machine will be tight first and loosen later to avoid dropping off the roll core.

4. Equipped with automatic alarm to indicate filling up of core pipe. The machine will be automatically stopped when there is no core pipes.

5. Automatic alarm for breaking off of paper.

6. Equipped separate tension control for each unwinding jumbo roll.

7. It is convenient to change the feature to produce any other core pipe winding.

8. Left paper remind after sealing of product for convenient use.

9. Jumbo roll stand is installed by pneumatic.

Technical parameters:

|

Model |

1800 |

2200 |

2800 |

|

Parent roll width |

1750 mm |

2150 mm |

2750 mm |

|

Dimension |

2512õ2470õ2944 mm |

2512õ2870õ2944 mm |

2512õ3470õ2944 mm |

|

Weight |

According to the parameters of machine | ||

|

Numbers of drive |

100 (others need order) | ||

|

Diameter of unwinding roll |

90-150 mm | ||

|

Speed |

20 pieces/min. | ||

|

Power |

2.2 kw | ||

|

Parent roll width |

1750 mm |

2150 mm |

2750 mm |

|

Parent roll diameter |

<1500 (>1500 need order) | ||

|

Parent roll core diameter |

76 mm(others need order) | ||

|

Size of finished product |

90-150 mm | ||

|

Size of central tube |

38-50 mm | ||

|

Perforating pitch |

4 knives ,90-160 mm (Others need order) 2 knives ,180-320 (Others need order) | ||

|

Perforator |

4 forged knives | ||

|

Parameter set |

Touching screener | ||

|

Programmable controller |

PLC, inverter | ||

|

Tension control system |

Encoder, PLC, inverter | ||

|

Mechanical controller |

Timing belts | ||

|

Engine |

380/50 V/Hz | ||

|

Pressure |

0.5-0.8 Mpa (need order) | ||