Description of high quality horizontal flotation deinking machine:

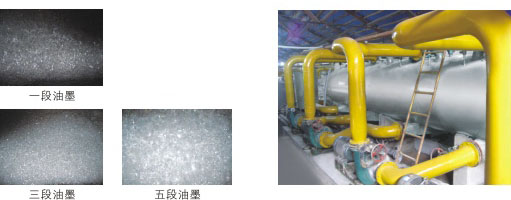

This machine is used to remove the hydrophobic impurity in the waste paper pulp, like ink particle, plastic, padding and so on. This equipment has around the flotation process to enhance the whiteness to be remarkable: 4-9 ISO, the textile fiber drains low<= 0.5%, the power consumption is only 1/2 or 1/3 of the traditional flotation process. The size range of the remove the ink particle is bigger, about 5-500 microns. Built-in aeration device is advantageous to the craft gas return route seal. Between the trough body combines reasonably, the fluid position control is simple, the movement is reliable, and the output scope is big. The flotation process system can removes impurity and printing ink in maximum limit, and guaranteed that the textile fiber outflow is smallest at the same time.

Functions and features:

1. It is designed with a built-in aeration component in favor of the process gas loop.

2. Owing to the reasonable combination of the troughs, it is easy to control fluid level, which results in reliable operation and a wide range of capacity.

Technical parameters:

|

Model |

GXT100 |

GXT200 |

GXT300 |

GXT400 |

GXT500 |

GXT600 |

GXT800 |

GXT1500 |

|

Capacity ( t/d ) |

10-20 |

30-40 |

40-60 |

60-80 |

80-100 |

100-120 |

120-180 |

180-300 |

|

Pressure of inflow pulp ( Mpa ) |

0.07-0.09 | |||||||

|

Inflow consistency (%) |

1.0-1.3 | |||||||